Transitional Housing - Prototype

Role: project lead / design - documentation - coordination

Company: AIDICO - Technological institute of Construction / Valencia, Spain

Client: Congo Government

Location: Design and concrete prototypes develop in Valencia, Spain

Year: 2010

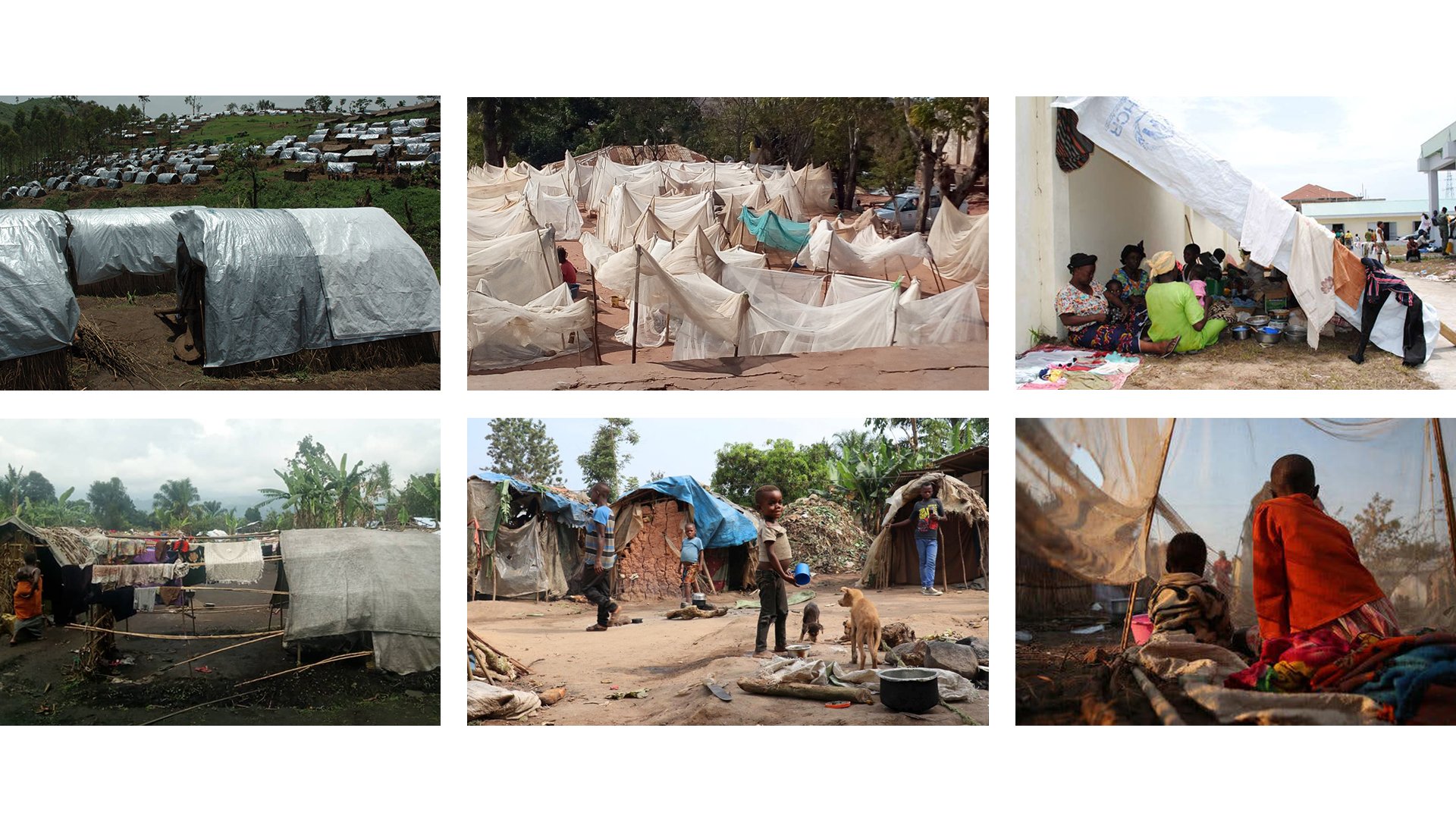

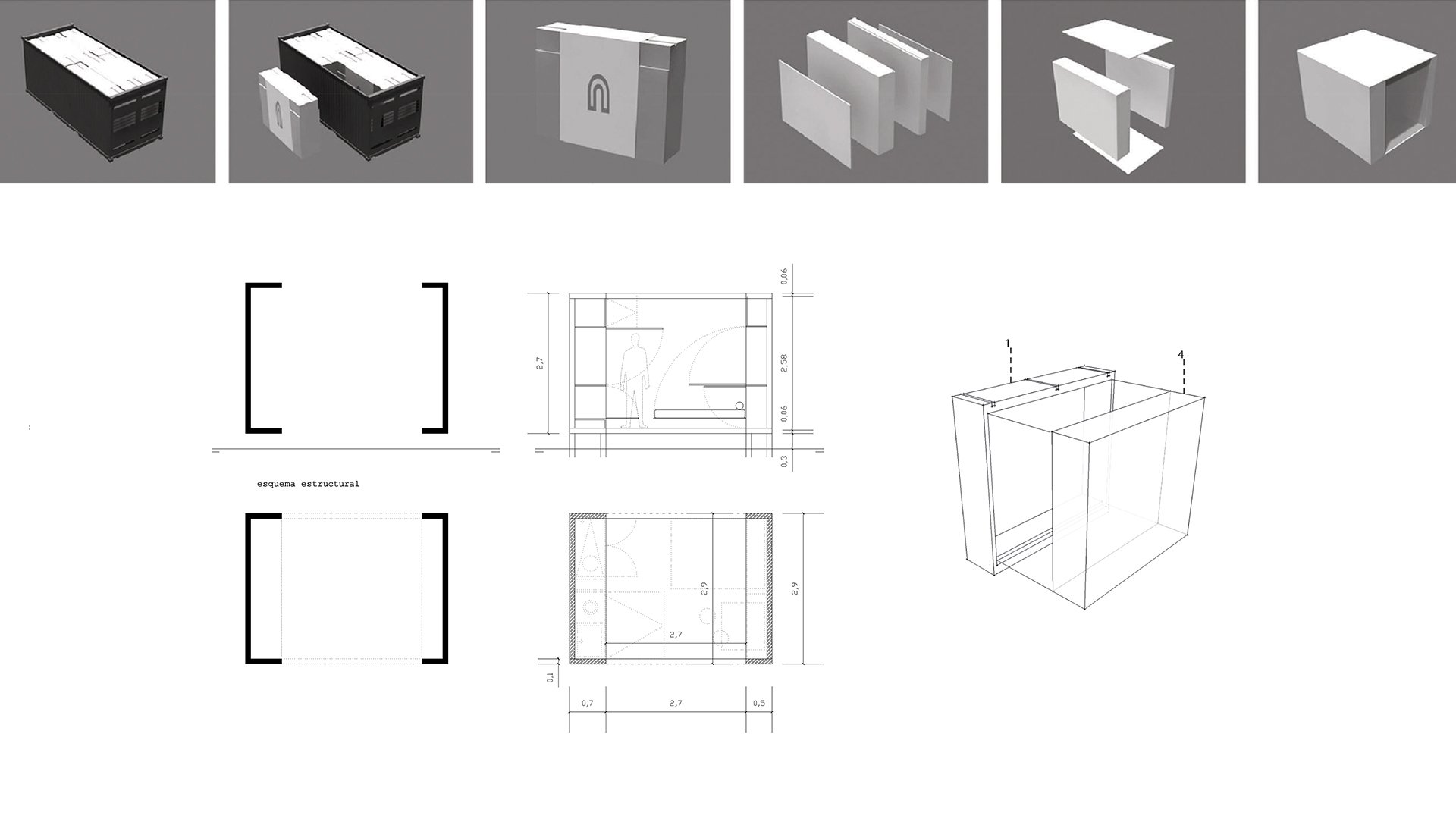

One in seven people lives in a refugee camp. The images selected are mostly from Africa, just because the context where this project was developed was in collaboration with the Government of Congo. However, the same issue extends worldwide. Tents are not considered transitional housing, and they are only meant to be temporary solutions. The reality is very different, and the tents become the final house. This project responds to a serious global problem, the lack of adequate housing.Initially, I was asked to transform containers into houses that hold all the necessities and that can be shipped and plugged into the new location. While researching the UN recommendations, I realized that this was not the best option. Since we were going to ship transformed containers, why not ship modules that can fit in the container and then use the containers for something else? Some of the containers could be used for community workshops, health care areas, community kitchens, etc. Unused containers go back to being shipping containers. Also, one container per house is less efficient than a few modules per container.

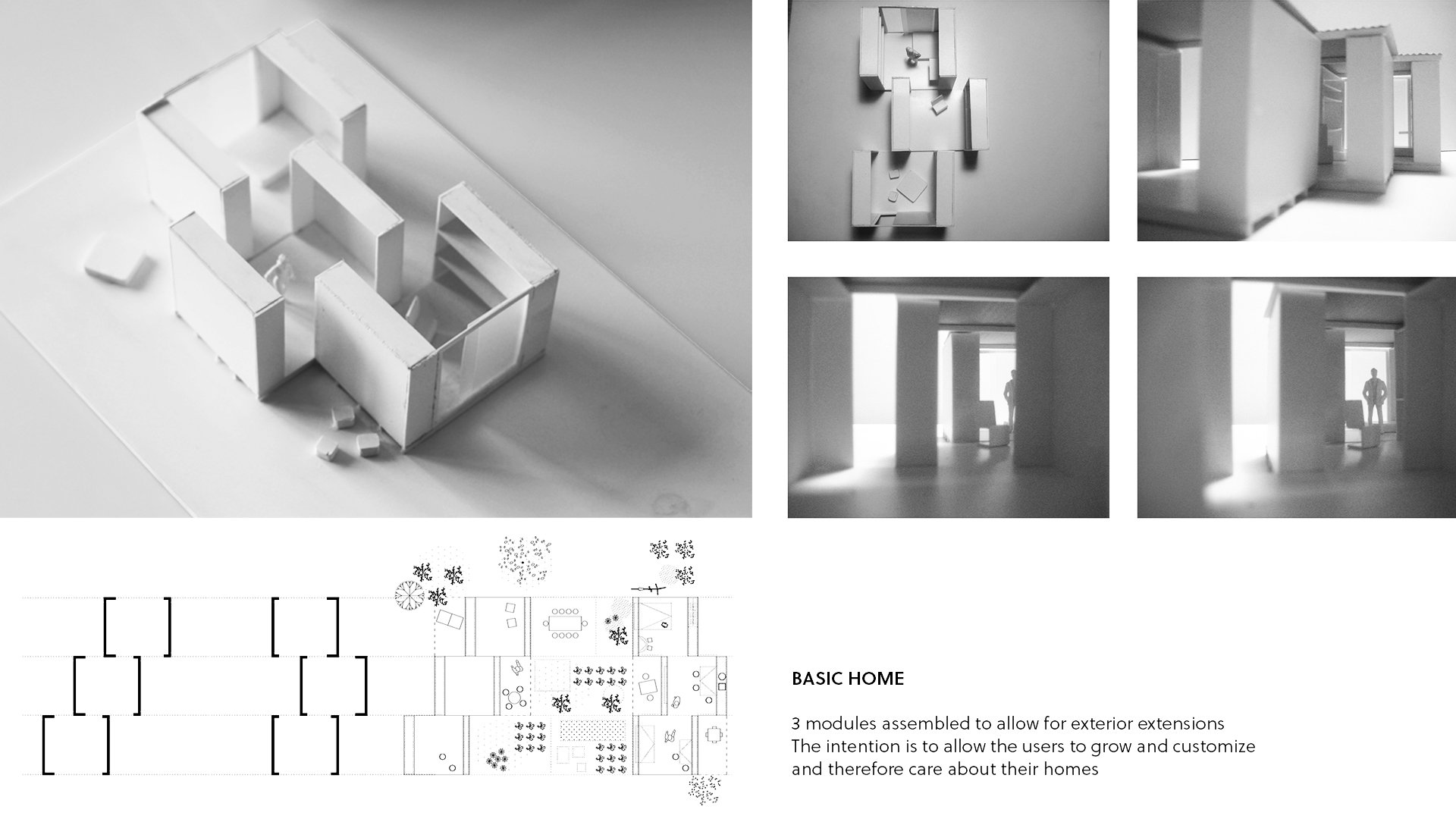

The aim of this project was to improve the current conditions of this type of housing, considering the possibility to expand and adapt to the needs of the occupants. Also, satisfy the urgency of homelessness.

For this, I proposed a module that is crafted as a piece of joinery that could be assembled easily on-site. The module consists of two opaque, hollow and rigid elements that contain the primary uses of the house. Two translucent parts are responsible for ventilation and light as well as allow the possibility of expansion and access, a roof and a floor plane. The pieces are dimensioned to facilitate their transport. Depending on the family members and necessities, more modules could be connected.

During the design development of the project, the biggest concrete manufacturing company in Spain got interested in the project and helped us develop some prototypes in precast concrete. The idea was that the modules could be done using different materials depending on the location and weather conditions.